How to Choose a Dunnage Bag Inflator

Dunnage bags are a cost-effective and efficient packaging solution for bracing and blocking cargo in transit. Dunnage bags have several advantages over other filling voids between cargo pallets, such as lumbar blockers or strap-downs, because they can fill all void spaces between cargo pallets. However, dunnage bags must be properly inflated for the best protection against damage.

What are dunnage bag inflators?

A dunnage bag inflator inflates dunnage bags to the appropriate sizes. When selecting an inflator tool, there are several factors to consider due to the various types of dunnage bag inflators available in the market.

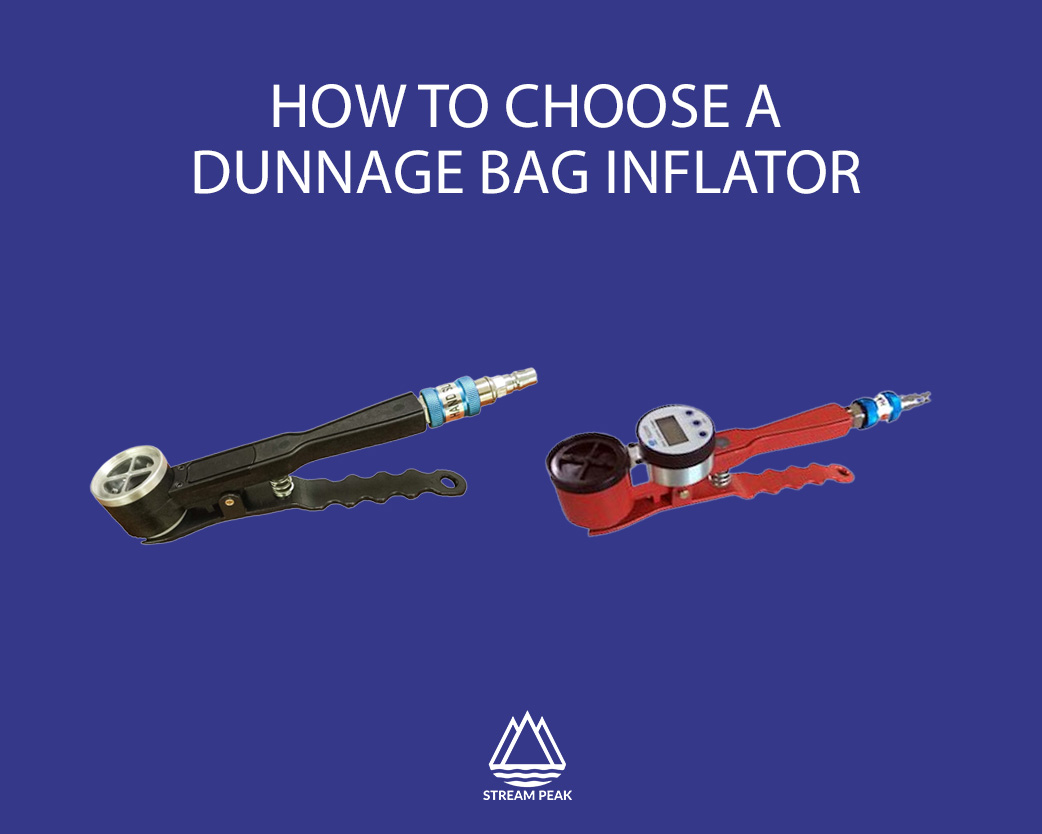

Types of dunnage bag inflators

There are two types of dunnage bag inflators: standard inflators that require an air supply (compressor) and battery-operated inflators. Do note that different manufacturers of dunnage bags use different types of valves, which means that not all inflation tools are compatible with all airbags.

Standard Inflators

A Standard Inflator is a traditional device that links an air compressor to a dunnage bag. An air compressor hose connects one end of the inflator to a deflated dunnage bag. The user then turns on the compressor and fills the bag with air until it is filled. This tool allows fast inflation of dunnage bags. It is easy to handle and has features like ‘finger-free design’ and ‘air pressure adjustment’. There are two types of standard inflators:

1) Standard Inflation Tool

The Standard Inflation Tool comes in two types of valve adapter – flexible rubber tube (40cm) and fixed steel pipe (20cm). Any standard air pressure system can be connected to the air gun. An optional manometer can be used and installed to preview the exact filling pressure.

2) Megaflow Venturi System

The Mega Flow Venturi Inflator fills dunnage bags with compressed air. The Mega Flow Venturi Inflator minimises operator error and fills dunnage bags 30 to 50 per cent faster than any other compressed air filling tool. It is specially designed to direct airflow up in a particular chamber. It creates a vacuum to draw more outside air into the dunnage bag.

Battery-operated Inflators

A battery-powered inflator is convenient as it allows users to inflate dunnage bags without using air lines or compressors. On the loading dock, it enables users to be entirely mobile as it has no cables or air hoses, and it can be worn in various ways to accommodate user preferences.

How to use dunnage bag inflators

1. Maintain the ‘lock ring’ of the locking device at the head of the inflator in an upper position.

2. Clip the valve adapter on the dunnage bag’s valve and the handle to hold it in position.

3. Aim the inflator’s locking device at the valve, the pin in the middle of the locking device should adhere to the column in the centre of the valve.

4. Now, press the valve base against the inflator from the back. Avoid touching the valve’s sealing bottom, or leave some space for it, then quickly press the inflator against the valve. The locking device’s ‘lock ring’ will lock the valve tight.

5. To start inflating, press the switch button on the inflation tool.

6. Pull the ‘lock ring’ to remove the valve from the inflator after inflation.

7. For added protection, cover the valve with a dust cap.

Points to consider before choosing a dunnage bag inflator

Dunnage Bag Suitability

Dunnage bags are manufactured in various sizes and materials depending on the load to be transported and the mode of transportation. The appropriate dunnage bag inflator varies as well. As a result, the dunnage bag must first be determined, followed by the suitable inflator tool.

Technical Specifications

The inflating of the dunnage bag follows the technical features of the inflator; therefore, it is essential to review the technical features of the inflator tool. These features include voltage, power, charging time, and air volume.

Functionality

The use and practicality of the dunnage bag inflator are essential since it facilitates the process. An inflator tool’s functionality is determined by its speed, weight, practicality, and durability. When deciding on the best inflator tool, it is essential to examine its function.

Inflator Features

Different inflator models have additional features. The general characteristics of the dunnage bag inflator are as follows:

- Inflation tools easily enter narrow gaps and provide ease of use due to their short length.

- Their lightweight allows ease of portability.

- They are resistant to hard impacts.

- They are long-lasting and cost-efficient.

- They are highly durable and do not break easily as they have an aluminium body.

- They are user-friendly.

- They can be used with various air compressor systems.

- The high-speed airflow allows the dunnage bag to be inflated in a short time.

Do’s and Don’ts in Dunnage bag Inflation, Installation and Deflation

Do’s

- Always use an approved inflator with a pressure gauge. Review and follow the instructions for the proper use of the inflator.

- Stand to one side, not directly in front of the dunnage bag.

- Use eye protection when filling

- While inflating and deflating, make sure to have a steady footing.

- Use regulator and filter in the air line.

- Check the pressure 30 minutes after inflation and re-inflate to the desired pressure if needed. (Poly woven dunnage bags stretch and can lose apparent pressure by stretching.)

- When inflating multiple dunnage bags in the same space, it is best to inflate from airbag to airbag to keep the air pressure uniform.

- Add protective material, like cardboard, between the bag and floor so that their bottoms will be a minimum of 1 inch (2.5 cm) above the floor after inflation.

- Use hold-down methods to prevent bag displacement from the void area. A standard hold-down way is to fold a sheet of corrugated cardboard and install it over the dunnage bag on either side before inflating. Once inflated, the cardboard sheet will be held in place by the dunnage bag.

Dont’s

- Do not exceed the maximum pressures.

- Do not inflate dunnage bag exceeding 12 inches (30 cm) of space.

- Do not use bags in tandem (back-to-back) in the same lengthwise row or space.

- Do not use dunnage bags to fill lengthwise space: between the front end wall and the 1st stack, between stacks, or between the last stack and the doors of the container.

- Do not stab a dunnage bag to deflate; use the spring dial on the valve.

With the load securement packaging solution, businesses can secure loads efficiently and effectively dunnage bags and dunnage bag inflators.